SOFC electrolyte powders can be used in various ways to enhance the performance of solid oxide fuel cells (SOFC). SOFC are electrochemical devices that convert chemical energy from a fuel and an oxidant into electricity and heat at high temperatures. Nexceris, through our FCM group, manufactures a variety of SOFC electrolyte powders of different materials depending on the desired properties and operating conditions, such as:

– Doped zirconium oxide (including yttrium (Y) or scandium (Sc)

– Doped cerium oxide (including gadolinium (Gd) or samarium (Sm)

– Barium zirconate based protonic conductors

Some of the best applications for these powders are:

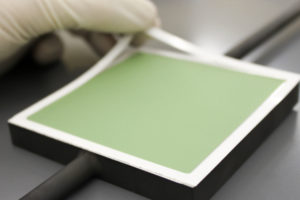

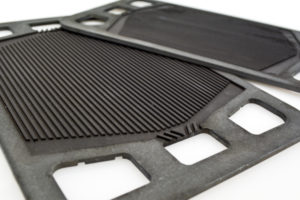

Cell supports – SOFC electrolyte powders can be used to form the backbone of the fuel cell, providing mechanical stability and electrical insulation. Supports can be made by shaping and sintering the powders into porous structures that allow gas diffusion and ion transport. The Nexceris designed NextCell is an electrolyte supported cell utilizing our patented Hionic™ scandium stabilized zirconia electrolyte and state-of-the-art anode and cathode materials in its design.

Barrier layers – SOFC electrolyte powders can be used to coat the supports or the electrodes to prevent unwanted reactions or intermixing between them. Barrier layers can improve the durability and efficiency of the fuel cell by reducing degradation and polarization losses.

Electrode layer additives – SOFC electrolyte powders can be added to the anode or cathode layers to improve their catalytic activity and conductivity. Electrode layers can be made by mixing the powders with binders and solvents and applying them onto the supports or barrier layers by methods such as screen printing, tape casting, or spray coating.

SOFC electrolyte powders are a critical component in a wide array of electrochemical applications. They can be tailored to suit different fuel cell designs and operating conditions, offering flexibility and versatility. SOFC electrolyte powders can help achieve higher power densities, lower emissions, longer lifetimes, and lower costs for SOFC systems. The electrolyte powders must have high ionic conductivity, low electronic conductivity, good chemical stability, and adequate mechanical strength to function effectively in a SOFC.

FCM offers many different formulations and surface area ranges to meet our customers’ needs. Additional information can be found on our SOFC electrolyte powders page. Small amounts of SOFC electrolyte powders and inks are available for researchers from our in-stock inventory for immediate delivery. In addition, FCM works with our commercial customers to provide larger production quantities. If special formulations are needed, please feel free to contact us. We will use our almost 30 years of experience with SOFCs and materials to ensure your needs are met.