FCM is a leader in the production of Lanthanum Strontium Gallium Magnesium Oxide (LSGM), a ceramic electrolyte material with high ionic conductivity. We are confident that we produce the highest quality electrolyte powders available with world-class characterization leading to increased performance.

LSGM electrolyte powders are widely used in solid oxide fuel cells (SOFCs) because of their high ionic conductivity and stability at high temperatures.

One of the most important aspects of using LSGM powders is to control the particle size distribution. Smaller particles can enhance the densification and reduce the grain growth of the electrolyte layer, leading to lower ohmic losses and higher performance. However, too small particles can also cause agglomeration and increase the sintering shrinkage, resulting in cracks and defects in the electrolyte layer. Therefore, it is essential to choose a suitable particle size range and to avoid excessive milling or grinding of the LSGM powders.

Micron-Submicron Electrolyte Powders

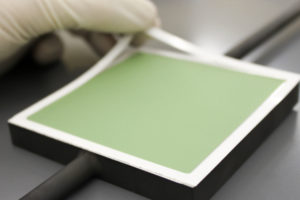

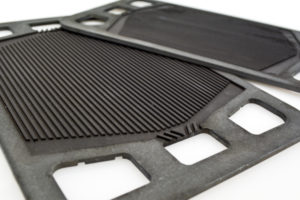

FCM offers a broad selection of micron to submicron powders, including LSGM. We leverage our years of expertise in powder research and production to assure the highest quality powders through composition purity. [See the images below as illustrations for how we provide the highest purity available, increased performance, and world-class characterization for our powders.]

LSGM requires careful selection and processing to achieve their best performance. FCM follows all of the best practices discussed in this article, such as controlling the particle size distribution, optimizing the sintering temperature and time, and considering the compatibility and integration with other components. This is how we can guarantee our LSGM powders are of the highest quality and provide the best reliability to meet your needs.

FCM offers many different formulations and surface area ranges to meet our customers’ needs. Additional information can be found at fuelcellmaterials.com. Small amounts of SOFC electrolyte powders and inks are available for researchers from our in-stock inventory for immediate delivery. In addition, FCM works with our commercial customers to provide larger production quantities. If special formulations are needed, please feel free to contact us. We will use our almost 30 years of experience with SOFCs and materials to ensure your needs are met.

Contact us below to learn more about our SOFC and SOEC technologies and how we can help you with your current projects.