Navitas Systems, a leader in next generation lithium ion energy storage systems, has developed world-class battery materials based on micro-porous silicon powder. The material has excellent performance in lab scale production, but process scale-up required a re-engineering for process economics and safety. In a collaborative development effort, Nexceris scaled production from grams to kilograms while reducing per kilo costs by a factor of 25.

About Navitas Systems

Navitas Systems is a leader in integrated design, technology development, and manufacturing, providing energy enabled system solutions and energy storage products for commercial, industrial and government agency customers.

Whether it is a new, rugged military product, critical medical application, or a renewable energy system, Navitas Systems offers a variety of battery chemistries, energy management systems, and engineering services to optimize a cost-effective, long lasting, and high performance solution.

Navitas products range from customized energy storage solutions for high power applications and custom renewable energy integration systems, to standard products like Lithium battery replacements in traditional Lead Acid applications.

Paving the Way for New Battery Chemistries Through Scaled Production

Navitas scientists and engineers had identified microporous silicon as a path to enhanced lithium ion battery performance. While several research teams had shown that microporous silicon provided excellent energy density and cyclability, the synthesis processes used in these efforts were of limited scale, with difficult paths to scalability.

Navitas identified a promising new approach that kept raw material costs low and process steps simple. Testing of laboratory-scale materials synthesis showed promise, and customers became interested in testing larger quantities of materials. However, scaling the new process would require the development of precisely controlled thermal treatment as well as unique electrode powder processes at a larger production scale.

The energy storage business moves fast; it would be difficult to develop such a process from scratch and implement in a short time frame. Navitas recognized that they needed a partner who understood their process requirements, had experience scaling the production of electronic powders, and could move quickly. After reviewing the Navitas process with the Nexceris product development team, it was clear to that there was a good match between organizations.

“By addressing materials compatibility and safety concerns early in the scale-up process, Nexceris has smoothed our path to larger quantities, while simultaneously reducing costs at the pilot-scale. This effort helps show our material and process can be used to meet challenging cost targets of the energy storage market.”

Pu Zhang, Director of Research, Navitas Systems.

Using Nexceris’ Proven Method to Save Time and Resources

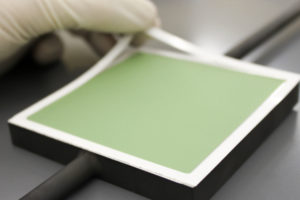

Figure 1. Nexceris’ LEVER Process for Product

Nexceris used its LEVER (Figure 1) approach for working with Navitas. The team Learned from Navitas their needs– discussions of the process requirements (end powder yield, features, economics and performance drivers) all took place before the first steps in the lab. Nexceris then tackled process scale-up by a deep review of adjacent technologies and engineering studies of materials selection and process development.

The team identified In-house technologies developed for processing corrosion coatings were used to cut the cost of heat treatment, while processes derived from literature review in the mining, electronics, and metals finishing industries were adopted to reduce the cost and enhance the safety of the powder processing.

Nexceris scientists Estimated the Benefit using production scale models of an envisioned process that increased production scale through, semi-continuous and continuous production. We created models of labor, capital equipment and materials costs to show how product cost would drop while maintaining product quality These estimates also showed the importance and value of addressing materials compatibility issues—at large scale, protective coatings or exotic materials can derail project economics; it was better to address these issues at the laboratory scale.

The team Validated that recommended process modifications would pay off, through lab-scale tests and delivery of powder for testing at Navitas. Each process was tested to confirm the crystal structure, physical properties and performance of the resulting powder met Navitas’ specifications. The validated processes were combined to create a scaled production line at Nexceris.

To Enhance the value of the work, the scaled process line was used to confirm process reproducibility and identify process control limits. In subsequent Reports, the cost model was revisited to identify the best remaining opportunities for process enhancement.

Measuring Progress on Metrics that Matter

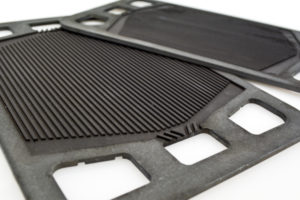

The Nexceris team successfully reduced the per kilogram cost of the material by a factor of 25 over the course of the development effort. The team implemented scaled heat treating technologies developed in-house and reduced the temperature of the powder processing by half, simplifying the selection of reactor materials. Process safety was improved through adopting new synthesis methods, reducing the capital costs of required safety equipment, improving worker comfort, and allowed unattended and automated operation.

The experimental work by Nexceris allowed the scale up of the Navitas process by more than an order of magnitude, from gram to kilogram batch sizes, with a defined path to larger quantities. The safety of the process was significantly enhanced and the process can be performed at modest temperatures using existing commercial process equipment, rather than specialty alloys and polymers necessary for the starting process. Together, these improvements have reduced the cost of the anode, making demonstrations economically practical.

Figure 2. Reduction in Materials Production Cost as a Function of Campaign Scale

“Working with Nexceris was a pleasure, and I look forward to future collaborations with them.”

Michael Wixom, Senior Director of R&D, Navitas Systems.

|

Let us help you reach production scale. |

|||

|---|---|---|---|

|

Use our expertise to take your production to the next level, just like Navitas Systems did. Contact Chris to get started!

|

|||