Protective Coatings for SOFC Components

Ceramic coating technologies have been demonstrated to mitigate the performance reduction caused by degradation of chromium-containing ferritic stainless steel alloys. fuelcellmaterials has taken the lead in tailoring and demonstrating cost effective coating technologies, including manganese cobalt oxide (MCO) and aluminide protective coatings for the metallic interconnects and balance of plant parts for solid oxide fuel cells (SOFCs).

Why You Need Protective Coatings for SOFC Components

Protective coatings are required to prevent failure of stainless steel SOFC components

Chromium Volatility

Substrate: cathode material in contact with Crofer 22APU

Condition: 100 h, humidified air 900 °C

Oxidation

Condition: 304 SS – 500 h, humidified air 900 °C

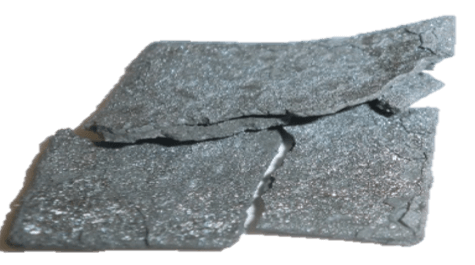

Coking/Carburization

Condition: 430 SS – 100 h, carbon rich atmosphere

fuelcellmaterials can assist through all phases of product launch.

Interconnect coating to your specifications

Prototype batches for process validation and stack tests

Parts are coated by our dedicated coating team

Contract coating batches for intermediate volumes

Early stage manufacturing to your specifications

Significant cost reductions for volume orders available

License product and transfer technology

Easily incorporate our technology into your manufacturing system

Materials supply agreements to ensure all your needs are met

ChromLokTM System

MCO Coating for Active Area of Interconnect Protection + Coatings for Seal Area Protection

The ChromLokTM process provides long term protection from chromium emission

fuelcellmaterials’ innovative ChromLokTM system provides metallic components used in solid-oxide fuel cell systems with the high-temperature protection they need. The ChromLokTM system includes a range of complementary oxide coatings that prevent the release of detrimental chromium species from stainless steels during high temperature operation. Coatings include a manganese cobaltite (MCO) coating, which combines excellent protection with low resistance, ideal for the cathode active-area where electrical conductivity is critical. Additional coatings include non-active, insulating coatings compatible with common seal materials and a Ni-based anode side coating.

To Learn More About How Our Coatings Can Impact Your Product, Contact Our Coatings Specialists

Sometimes it’s just easier to make a phone call. Feel free to call us at +1.614.635.2025 anytime, although we are only here from 9AM-6PM EST Monday – Friday, if that changes anything.

Excellent long term stability for over 50,000 hours demonstrated

Electrical ASR performance of MCO coated ferritic stainless steel

Substrate: AL 441-HP Temperature: 800 °C – 900 °C

Gas composition: humidified air (~ 3 % H2O) Current density: 0.5 A/cm2

MCO coating enables cathode active protection of metallic interconnects

ChromLokTM Microstructure

After Deposition

800 hrs 800 °C

> 7000 hrs 800 °C/900 °C

Top Down MCO Coating

Cross Section MCO Coating

Coating: MCO oxidized

Substrate: ferritic stainless steel Crofer 22APU

AlumiLokTM Coating

High Temperature Corrosion Protection for Balance of Plant Parts

AlumiLokTM coating is amenable to high temperature protection of BoP components

The AlumiLokTM coating process is a scalable, cost-effective approach to protect metal components from corrosion in high-temperature applications. Coated stainless steel components exhibit eight to ten times less oxidation, greatly exceeding the performance of other high temperature alloys. AlumiLokTM has been shown to work with a wide range of materials, including ferritic & austenitic stainless steels, Inconel, nickel alloys & copper alloys. AlumiLokTM replicates the traditional aluminization surface microstructure, proving just as effective as the expensive vapor phase aluminization process.

To Learn More About How Our Coatings Can Impact Your Product, Contact Our Coatings Specialists

Sometimes it’s just easier to make a phone call. Feel free to call us at +1.614.635.2025 anytime, we are only here from 9AM-6PM EST Monday – Friday, but you can leave a message and trust we will get back to you as soon as we can.

Coating reproduces the microstructure produced by conventional aluminization processes

AlumiLokTM Microstructure

Aluminide Coating (AlumiLokTM)

Vapor-Phase Aluminization (VPA)

Substrate: 316 stainless steel

Aluminide coating: standard processing

AlumiLokTM coating significantly improves oxidation behavior of stainless steels

AlumiLokTM Oxidation Behavior

|

AlumiLokTM Coated |

|

Uncoated |

Substrate: 316 stainless steel

Temperature: 900 °C

Gas composition: humidified air

Resistance to coking in high carbon gas streams

AlumiLokTM Coking Behavior

Uncoated

Coated

Substrate: 316 stainless steel

Exposure time: 100 hours

Temperature: 550 °C

Gas composition: 33 % H2, 30 % CO2, 24.7 % CO, and 12 % CH4

Pressure: 4 psi