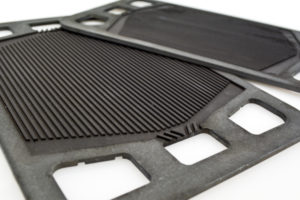

A prominent SOFC developer engaged Nexceris to identify a protective coatings solution for their metallic interconnects. The customer required a cost-effective protective coating to mitigate against oxidation and chromium volatilization from the steel substrate during SOFC operation that could be scaled to mass production volumes.

Nexceris worked closely with the customer to demonstrate the applicability of its ChromLokTM SOFC interconnect coating technology, from initial proof-of-concept validation, through intermediate pilot-scale manufacturing at Nexceris’ dedicated coating facility, to a licensed high-volume coating solution that was successfully transferred to the customer’s production facility. A partnership was developed to ensure that the customer’s needs and time requirements were met at every decision point. With the ChromLokTM coating technology in place, our partner is well on its way to achieving its SOFC commercialization goals.

About our Partner

The protection of our partner’s physical and intellectual property is very important to Nexceris. All non-essential personnel are fire-walled from customer property activities to ensure there is no cross-contamination of information at the Nexceris facility. In the spirit of keeping our partner’s information secure, we are not including their name or other details in this case study.

The Challenges

In order for all SOFC developers to break into their targeted energy markets, a durable, cost competitive product is needed; our partner is no different. Nexceris’ partner identified the interconnect as the best area of the SOFC to improve their market position. Nexceris has been coating metallic interconnects in-house for this industry leader in prototype and pilot scales for a few years to improve stack durability and longevity. However, in order for the customer to make their system economical in the marketplace, a different manufacturing model was necessary for high volume production.

Working together, it was decided that Nexceris would license the coating technology and set up a coating line at the partner’s Asian facility. Nexceris’ understanding of the requirements of the customer and the SOFC market, enabled process development to be aligned with providing a solution amenable to high-volume production.

“The technology transfer has been a very rewarding experience. There was a great sense of accomplishment after working closely with our partner over several years to see our pilot-scale coating technology successfully transitioned to their facility.”

Neil Kidner, Ph.D., Principal Engineer, Nexceris

The Solution

Using Nexceris’ Proven Method to Deliver a Scalable and Cost-Effective Solution

Figure 1. Nexceris’ LEVER Process for Product

Nexceris deployed its proven LEVER (Figure 1) approach to maximize the effort to achieve a successful outcome. The team Learned the most important customer requirement – exceptional quality protection of the metallic interconnect used in their solid oxide fuel cell (SOFC) stacks. During early prototyping, and initial proof-of-concept stage it was critical that Nexceris understood the specific concerns of our partner. These included identifying a coating solution that could satisfy our partner’s technical requirements, including low area-specific resistance, effective oxidation and chromium volatility resistance, and long-term stability under high temperature conditions.

In parallel it was critical that any coating approach have a viable roadmap to our partner’s eventual volume and cost targets. Nexceris engineers provided high-fidelity Estimates of manufacturing costs and the best options for cost reductions. This established a roadmap that enabled process development to be aligned with providing a solution amenable to high-volume production.

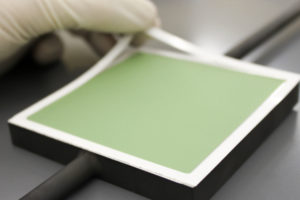

During the initial proof-of-concept, Nexceris Validated the ChromLokTM coating by providing coated samples and interconnects for joint evaluation. Establishment of a fast development cadence was critical for Nexceris to ensure on-time delivery of these evaluation parts to ensure the customer was able to complete all the required validation testing as scheduled.

To Enhance the value of the work, Nexceris worked closely with our partner to identify opportunities to improve both the performance of the coating and the coating process. Various process and formulations were systematically evaluated, including powder formulation and surface area, suspension formulation and coating parameters.

Once Nexceris had demonstrated a successful coating that satisfied our partner’s requirements, it was able to use its manufacturing capability as a bridge to support our partner’s larger validation and demonstration projects. Nexceris worked to grow its coating facility to support pilot-scale production, hiring additional production technicians, and installing and qualifying additional furnace capacity. This enabled coating production to increase from 50 parts/month to thousands of parts per month. As the process transitioned from development to pilot-scale production, Nexceris Reported information through detailed production batch records and datasheets, and QA/QC measures to ensure the production of high-quality coated interconnects. At every stage, it was important to ensure the pilot-production processes would scale to high-volume.

The Results

To satisfy our partner’s high-volume production demand, a licensed technology transfer was developed to enable the ChromLokTM technology to be transferred to our partner’s production facility. Nexceris worked on-site to ensure the complete transfer of information. Nexceris also published a 400 plus page book to aid our partner before, during, and after technology transfer. The published book detailed statistical process control charts of key process operations to monitor pilot-scale production were established, and fully defined Process Flow Diagrams (PFDs), Process Control Plans (PCPs) and Process Failure Mode Effects Analysis (PFMEAs) to report all stages of production created. These reports were integrated with detailed work instructions for all process operations, information on production equipment and raw materials supply chain.

The partner has starting using Nexceris’ ChromLokTM coating technology in its facility and is working to achieve its commercialization goals. With the coating process in house the partner has demonstrated a reduction in lead time, cost per part, and a clear path to higher manufacturing volumes.

Nexceris continues to provide technical assistance to the customer as their coating facility comes online while continuing to be a supplier of coated parts to ensure a good supply chain.

|

Let us help you reach production scale. |

|||

|---|---|---|---|

|

Use our expertise to take your production to the next level, just like our partner did. Contact Chris to get started!

|

|||