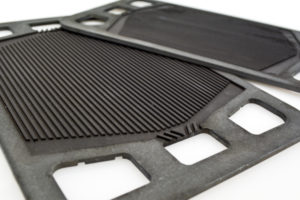

fuelcellmaterials offers a variety of substrate components for the development of solid oxide fuel cells. Gadolinium Doped Ceria (GDC or CGO), Yttria-Stabilized Zirconia, and our patented Hionic™ substrates are available in multiple sizes, including 20 mm to 32 mm buttons and 5 cm x 5 cm and other planar sizes. The choice of substrate size, geometry and material is based on the specific types of tests you are performing, the requirements of your test apparatus, the targeted operating temperature for the fuel cells you are developing, or the specific SOFC materials you are developing. The following describes electrolyte materials selection aspects you should consider:

Yttrium Stabilized Zirconia (8 mole percent Y2O3) is the most commonly used electrolyte material for solid oxide fuel cells, based on its stability over a wide range of oxygen partial pressure and its relatively low materials cost. A challenge associated with YSZ is that it reacts with commonly used cathodes, so a barrier layer (typically ceria-based electrolyte) is applied between the YSZ and the cathode coating. YSZ substrates should be considered as a standard for comparing alternative electrolyte materials and also as a platform for developing ceria barrier layers and other SOFC materials.

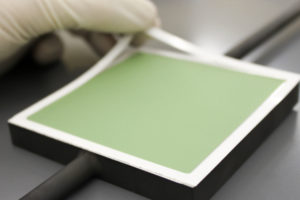

Hionic™ Substrates

Our patent pending Hionic™ substrate is based on Scandia stabilized zirconia, which has much higher ionic conductivity and better mechanical strength compared to YSZ. The higher conductivity of the Hionic™ substrate increases power density, and the better mechanical strength enables large-area substrates to be made with lower thicknesses (improving both power density and handling). It should be noted that Hionic™ substrates also require ceria barrier layers to prevent reaction with commonly used cathode materials. Our Hionic™ substrates are ideal for single-cell SOFC testing, both at button and large-area scales.

Gd-doped ceria is a low-temperature electrolyte material and can be used for SOFCs operating at temperature less than about 600 °C (and cannot be used as an electrolyte at higher temperatures due to reduction issues). An advantage of GDC is that it is non-reactive with LSCF and other high performance cathodes. This makes GDC electrolyte substrates ideal for cathode material development studies (where tests are conducted in air) because barrier layers are not required.

Substrate Supplier

Working with quality SOFC substrate providers is just as important as having the most effective substrate for your application. A quality supplier will ensure uniform substrates from batch to batch so you have repeatable and reliable results. You will also benefit from working with a supplier in the SOFC industry, since they will be knowledgeable on your application and understand the requirements for success.

Better Together

When you work with FCM, you are working with a team of SOFC experts who are dedicated to ensuring your projects are successful. Learn how FCM can help you by filling out the form below.