One of the most important steps to get right when building your stack or performing single cell testing is the sealing process. Making a good seal ensures that the fuel (hydrogen, carbon monoxide and methane) flows towards the cell to generate power, and is not lost to the environment inside your testing lab. In most SOFC designs there is a back-pressure imparted on the fuel feed by the exhaust tubing, manifold and architecture of the anode cavity. Hydrogen being the lightest and smallest elemental gas even a small back-pressure is enough to enable it to escape from the anode cavity. There are several different sealing options available to researchers, each having their own strengths and weaknesses as described below.

Our alumina felt seals is a compressive seal and is easy to assemble and use. These seals can be cut into any shape and are relatively low cost options for your entry level or startup testing purposes. After positioning the seal around your cell you want to infuse it with alumina slurry to fill in the porosity, this can be achieved by taking a pipette or eye dropper and adding the slurry around the edges until it is saturated enough when compressed. You do not want to soak the felt as this will then leak slurry during the compression stage. It is normal for the alumina slurry can separate after sitting on the shelf for a while, so make sure to shake the bottle vigorously before using. After assembling your test cell make sure to apply enough compressive pressure that a good seal is made. The seal can be fired in-situ with the rest of your testing apparatus.

Glass Sealing Technology

Another technology that is used for SOFC sealing are glass seals. These seals work very well at bonding materials with similar thermal expansion, especially Crofer to Crofer. After curing at a high temperature, the glass acts as a very good seal at your specified operating temperature. Using these seals directly on the ceramic support of your fuel cell however may result in a shattered component as the different materials expand at different rates, which is why researchers are also using composite glass-alumina seals when bonding metals to ceramic.

If you are looking to make a tight seal between your manifolds without compression, then high temperature sealing paste is the way to go. This paste will form a gas-tight seal around the edges of your manifolds and can be used in button cell testing. Apply the paste around the edges of your sealing area and let it dry at room temperature. You can cure it either before use or in-situ with your test assembly. After use you may need to use a hand-held rotary tool to remove the paste, and polish the metal again before the next test.

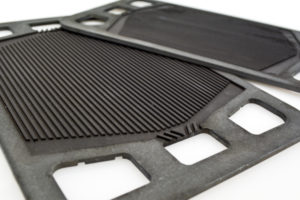

Several different examples of these include Mica Paper and Thermiculite. Unlike the alumina felt seals these do not require any infusions of slurry but work on compression alone. When using this in combination with one of the furnaces that we offer, compression is given by an adjustable weight on the side that provides torque. Thermiculite seals are specifically designed to give good sealing at low surface stresses, and sealing is not reduced by thermal cycling.