SOEC electrolyte powders are materials that enable the operation of solid oxide electrolyzer cells (SOECs), which are devices that use high-temperature electrolysis to split water and/or carbon dioxide into hydrogen, oxygen and/or carbon monoxide.

SOEC electrolyte powders are usually composed of doped zirconium oxide (including yttrium (Y) or scandium (Sc) or doped cerium oxide (including gadolinium (Gd) or samarium (Sm), which provide high ionic conductivity and stability at elevated temperatures.

Some of the best applications for SOEC electrolyte powders are:

- Hydrogen production – SOECs can produce pure hydrogen gas from water steam, which can be used as a clean fuel or a chemical feedstock. Hydrogen production by SOECs is more efficient and environmentally friendly than conventional methods, such as steam reforming or water electrolysis at lower temperatures. Hydrogen can also be stored and transported more easily than electricity, making it a potential alternative to batteries and other energy sources.

- Syngas production – SOECs can also produce syngas, a mixture of hydrogen and carbon monoxide, from water and carbon dioxide. Syngas can be used as a synthetic fuel or a precursor for various chemicals, such as methanol, ammonia and Fischer-Tropsch products. Syngas production by SOECs can utilize waste carbon dioxide and reduce greenhouse gas emissions, while also creating valuable products.

- Oxygen production – SOECs can produce pure oxygen gas from carbon dioxide, which can be used for various purposes, such as medical, industrial or aerospace applications. Oxygen production by SOECs can also help mitigate the effects of global warming by removing excess carbon dioxide from the atmosphere.

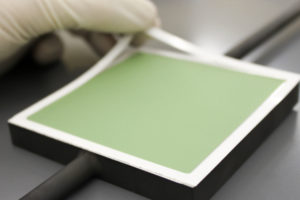

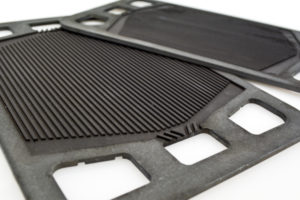

FCM offers many different formulations and surface area ranges to meet our customers’ needs. Additional information can be found on our SOFC electrolyte powders page. Small amounts of SOEC electrolyte powders and inks are available for researchers from our in-stock inventory for immediate delivery. In addition, FCM works with our commercial customers to provide larger production quantities. If special formulations are needed, please feel free to contact us. We will use our almost 30 years of experience with SOFCs and materials to ensure your needs are met.