Nexceris was honored to give a presentation at the 13th European SOFC & SOE Forum on our development of various SOFC interfaces created by aerosol-spray deposition. Our Director of Materials Science, Neil Kidner, gave a talk on July 4th at the conference, which is held every two years in beautiful Luzern, Switzerland. Nexceris has developed multiple spray coating technologies, including the ChromLokTM electrically conductive coating for interconnects, AlumiLokTM protection coating, SupircatTM internal reforming coating, GasLokTM coating for seals, and CeriLokTM as part of our cell development and manufacturing process. These technologies are part of our strategy as a company to create a better world through energy innovations.

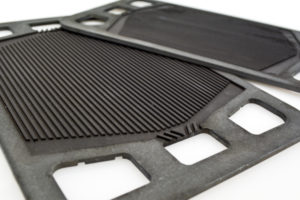

Our coating microstructure enables a range of applications, including stopping oxidation and chromium volatility, and improving coking resistance on interconnects and balance of plant through our improved AlumiLokTM coating. Manifolds coated with AlumiLokTM prevent deactivation and help to maintain cell potential over time.

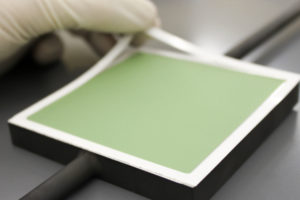

The CeriLokTM coating is a spray-based barrier layer that we developed to prevent resistive phase formation at the electrolyte and cathode interfaces. For zirconia-based electrolytes, such as YSZ or ScSZ, an interfacial layer occurs which disrupts performance of the cell at high temperatures. For low temperature applications, the CeriLokTM process significantly improves performance of the cell, both in cell potential and power density. This technology can be used and has been shown to be successful in both electrolyte supported cells (ESC) and also in anode supported cells (ASC).

Please visit the link below to see the full presentation, and if you have any questions about this technology, please contact Dr. Kidner at n.kidner@nexceris.com.