What are lanthanum-based cathode powders and how are they used? What are the best applications for lanthanum cathode powders?

Lanthanum cathode powders are materials that can be used in various electrochemical applications, such as solid oxide fuel cells (SOFCs), solid oxide electrolysis cells (SOECs), oxygen separation membranes, mixed conducting membranes, and gas sensors.

Lanthanum cathode powders are composed of lanthanum and other elements, such as strontium, cobalt, nickel, etc., forming perovskite structures that exhibit high ionic and electronic conductivity, as well as catalytic activity for oxygen reduction reaction (ORR). Depending on the composition and operating conditions, lanthanum cathode powders can have different properties, such as thermal expansion coefficient, surface area, particle size, sintering temperature, etc., which affect their performance and durability.

Types of Lanthanum Cathode Powders

One of the most common types of lanthanum cathode powders is lanthanum strontium manganite (LSM), which has been widely used in SOFCs with zirconia-based electrolytes at operating temperatures above 750 °C. LSM has a high catalytic activity for oxygen reduction and a low coefficient of thermal expansion, which matches well with the electrolyte material. LSM is typically prepared by solid-state reaction or co-precipitation methods, followed by calcination and milling to obtain fine particles with a desired size distribution and surface area.

Another type of lanthanum cathode powder is lanthanum strontium cobalt ferrite (LSCF), which is suitable for SOFCs with lower operating temperatures (below 750 °C) and anode-supported designs. LSCF has a higher electronic conductivity and oxygen diffusion coefficient than LSM, which results in lower polarization losses and higher power density.

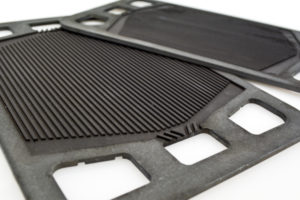

A third type of lanthanum cathode powder is lanthanum strontium cobaltite (LSC). LSC is often used as a contact paste between the cathode and the current collector in SOFC systems, where it provides a good electrical contact and a low contact resistance. LSC can be easily fabricated into an ink for painting or screen printing.

Lanthanum nickel cobaltite (LNC) is a material used to improve the performance and durability of solid oxide fuel cells (SOFCs). LNC is a compound with high electrical conductivity and thermal stability. LNC cathode powder can be mixed with ceria-based electrolyte powders to form a cathode layer or used as a contact paste to enhance the current collection of the cathode. LNC cathode powder is suitable for low-temperature applications and multilayer cathodes.

Our Approach to Fabricating Lanthanum-Based Cathode Powders

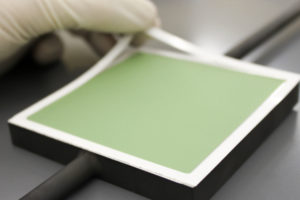

Lanthanum-based cathode powders can be fabricated into inks for screen printing or painting on various substrates. Lanthanum-based cathode powders can also be used as contact pastes or current conducting materials for multilayer cathodes. Some of the advantages of using lanthanum-based cathode powders are their low cost, high availability, and environmental friendliness. The performance of the cathode depends on several factors, such as the composition, particle size, surface area, porosity, and microstructure of the powder, as well as the operating conditions of the fuel cell.

Why Work With FCM

FCM offers many different formulations and surface area ranges to meet our customers’ needs. Small amounts of powders and inks are available for researchers from our in-stock inventory for immediate delivery. In addition, FCM works with our commercial customers to provide larger production quantities. If special formulations are needed, please feel free to contact us. We will use our almost 30 years of experience with SOFCs and materials to ensure your needs are met.

FCM offers many different formulations and surface area ranges to meet our customers’ needs. Additional information can be found on our Cathode Powders Page. Small amounts of SOEC electrolyte powders and inks are available for researchers from our in-stock inventory for immediate delivery. In addition, FCM works with our commercial customers to provide larger production quantities. If special formulations are needed, please feel free to contact us or use our custom materials form. We will use our almost 30 years of experience with SOFCs and materials to ensure your needs are met.